Image 1 of 2

Image 1 of 2

Image 2 of 2

Image 2 of 2

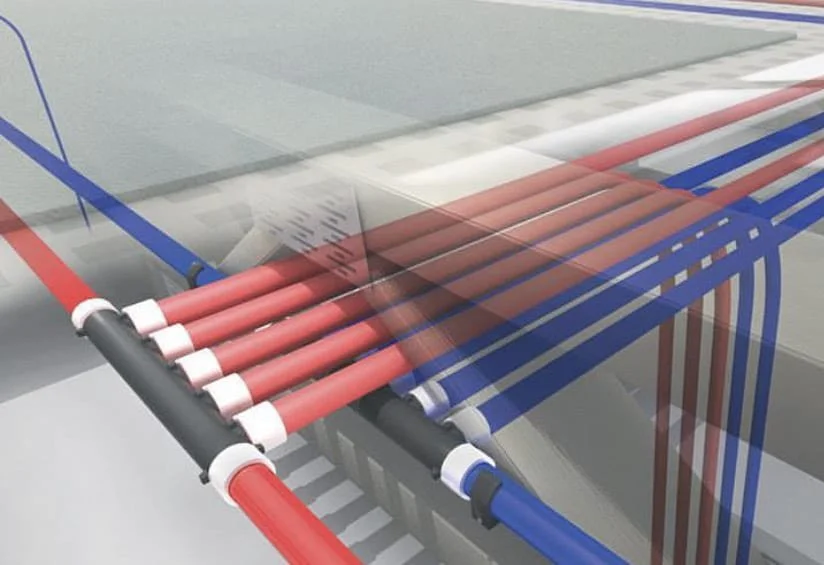

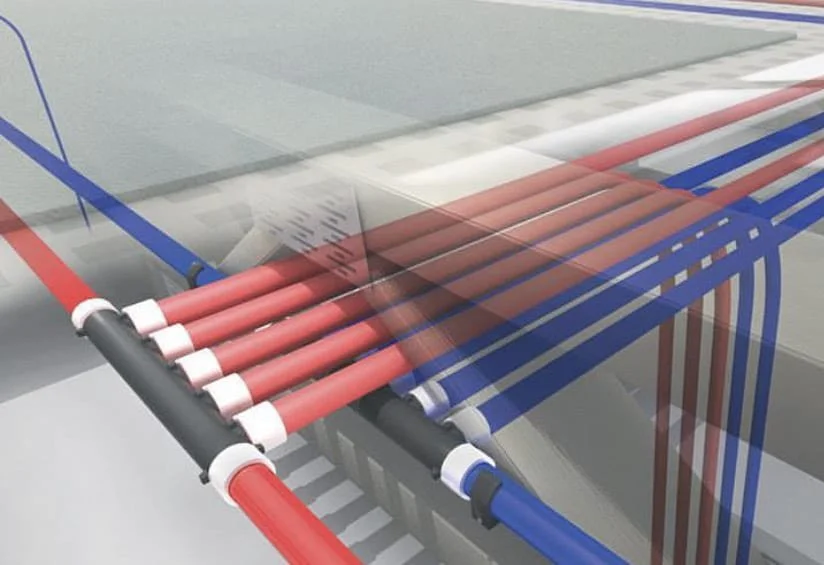

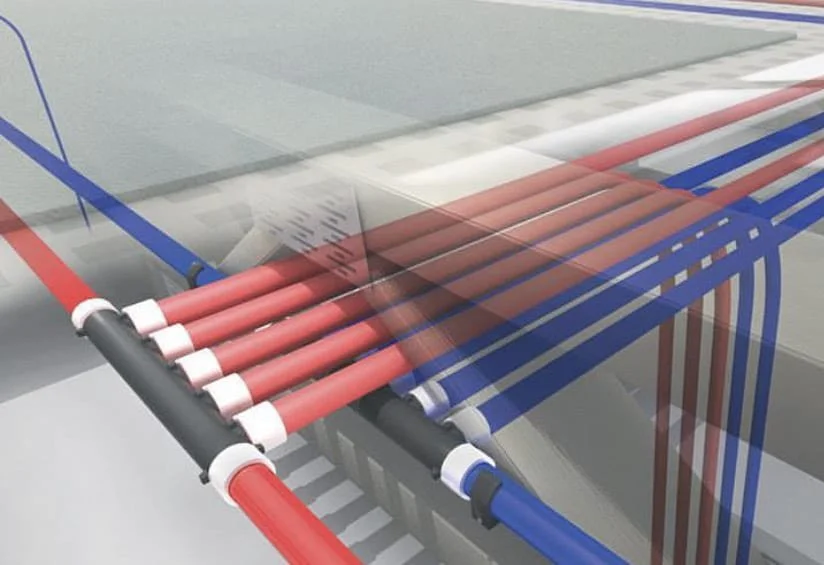

Repipe of water distribution system

Repiping is the process of removing and replacing the pipes that deliver potable water throughout a home, including hot and cold water lines. It typically addresses the interior water distribution system (from the point where water enters the home to fixtures like sinks, showers, and appliances) but may also include exterior lines in some cases. Repiping is distinct from drain or sewer line replacement, as it focuses solely on the supply lines.

Why Repipe a Home?

Repiping is often necessary due to:

• Aging Pipes: Older homes (pre-1970s) may have galvanized steel pipes that corrode, rust, or develop mineral buildup, reducing water pressure and quality.

• Frequent Leaks: Persistent leaks or pinhole leaks in copper or galvanized pipes signal deterioration.

• Material Issues: Outdated materials like lead pipes (pre-1986) or polybutylene (1970s–1990s) pose health risks or are prone to failure.

• Low Water Pressure: Corrosion or buildup inside pipes restricts flow.

• Water Quality Problems: Rust, sediment, or contamination from deteriorating pipes affects taste, color, or safety.

• Renovations or Upgrades: Repiping may accompany home remodeling to meet modern plumbing codes or support new fixtures.

• Energy Efficiency: Insulated hot water lines (e.g., PEX) reduce heat loss, lowering energy costs.

Common Materials for Repiping

Modern repiping typically uses one of two materials, chosen based on durability, cost, and local codes:

1. Copper:

• Pros: Durable (50+ years), resistant to corrosion, handles high temperatures, and provides clean water. Widely accepted by building codes.

• Cons: Expensive (material and labor), rigid (harder to install in tight spaces), and susceptible to freezing or pinhole leaks in rare cases.

• Use Case: Preferred for homes in areas with aggressive water chemistry or where long-term reliability is prioritized.

2. PEX (Cross-Linked Polyethylene):

• Pros: Affordable, flexible (easier to install, especially in retrofits), resistant to corrosion and freezing, and reduces heat loss in hot water lines. Available in colors (red for hot, blue for cold) for easy identification.

• Cons: Shorter lifespan (25–50 years), potential for UV damage (must be shielded from sunlight), and some concerns about chemical leaching in low-quality PEX (though modern PEX is safe).

• Use Case: Ideal for cost-conscious homeowners, complex layouts, or areas prone to freezing.

3. CPVC (Chlorinated Polyvinyl Chloride):

• Pros: Cheaper than copper, corrosion-resistant, and easier to install than copper.

• Cons: Less flexible than PEX, can become brittle over time, and has a shorter lifespan (20–40 years).

• Use Case: Less common but used in budget repiping projects where PEX isn’t preferred.

Note: Lead, galvanized steel, and polybutylene are no longer used due to health risks, corrosion, or unreliability. Local codes may dictate material choices.

Potential Challenges

• Access Issues: Pipes behind walls, under slabs, or in tight spaces increase labor and repair costs.

• Code Compliance: Local codes may require specific materials, insulation, or shutoff valves, adding complexity.

• Unexpected Damage: Removing old pipes can reveal structural issues (e.g., mold or rot from past leaks), requiring additional repairs.

• Material Compatibility: Mixing old and new materials (e.g., copper with galvanized) can cause galvanic corrosion, so full replacement is often advised.

• Temporary Inconvenience: Homeowners may need to relocate or use portable facilities during the project.

Benefits of Repiping

• Improved Water Quality: Eliminates rust, lead, or sediment for safer, better-tasting water.

• Better Pressure and Flow: New pipes restore optimal water pressure and reduce clogs.

• Fewer Repairs: Reduces the need for frequent leak fixes, saving money long-term.

• Increased Home Value: Modern plumbing appeals to buyers and meets code standards.

• Energy Savings: Insulated PEX or copper reduces heat loss in hot water lines.

Repiping is the process of removing and replacing the pipes that deliver potable water throughout a home, including hot and cold water lines. It typically addresses the interior water distribution system (from the point where water enters the home to fixtures like sinks, showers, and appliances) but may also include exterior lines in some cases. Repiping is distinct from drain or sewer line replacement, as it focuses solely on the supply lines.

Why Repipe a Home?

Repiping is often necessary due to:

• Aging Pipes: Older homes (pre-1970s) may have galvanized steel pipes that corrode, rust, or develop mineral buildup, reducing water pressure and quality.

• Frequent Leaks: Persistent leaks or pinhole leaks in copper or galvanized pipes signal deterioration.

• Material Issues: Outdated materials like lead pipes (pre-1986) or polybutylene (1970s–1990s) pose health risks or are prone to failure.

• Low Water Pressure: Corrosion or buildup inside pipes restricts flow.

• Water Quality Problems: Rust, sediment, or contamination from deteriorating pipes affects taste, color, or safety.

• Renovations or Upgrades: Repiping may accompany home remodeling to meet modern plumbing codes or support new fixtures.

• Energy Efficiency: Insulated hot water lines (e.g., PEX) reduce heat loss, lowering energy costs.

Common Materials for Repiping

Modern repiping typically uses one of two materials, chosen based on durability, cost, and local codes:

1. Copper:

• Pros: Durable (50+ years), resistant to corrosion, handles high temperatures, and provides clean water. Widely accepted by building codes.

• Cons: Expensive (material and labor), rigid (harder to install in tight spaces), and susceptible to freezing or pinhole leaks in rare cases.

• Use Case: Preferred for homes in areas with aggressive water chemistry or where long-term reliability is prioritized.

2. PEX (Cross-Linked Polyethylene):

• Pros: Affordable, flexible (easier to install, especially in retrofits), resistant to corrosion and freezing, and reduces heat loss in hot water lines. Available in colors (red for hot, blue for cold) for easy identification.

• Cons: Shorter lifespan (25–50 years), potential for UV damage (must be shielded from sunlight), and some concerns about chemical leaching in low-quality PEX (though modern PEX is safe).

• Use Case: Ideal for cost-conscious homeowners, complex layouts, or areas prone to freezing.

3. CPVC (Chlorinated Polyvinyl Chloride):

• Pros: Cheaper than copper, corrosion-resistant, and easier to install than copper.

• Cons: Less flexible than PEX, can become brittle over time, and has a shorter lifespan (20–40 years).

• Use Case: Less common but used in budget repiping projects where PEX isn’t preferred.

Note: Lead, galvanized steel, and polybutylene are no longer used due to health risks, corrosion, or unreliability. Local codes may dictate material choices.

Potential Challenges

• Access Issues: Pipes behind walls, under slabs, or in tight spaces increase labor and repair costs.

• Code Compliance: Local codes may require specific materials, insulation, or shutoff valves, adding complexity.

• Unexpected Damage: Removing old pipes can reveal structural issues (e.g., mold or rot from past leaks), requiring additional repairs.

• Material Compatibility: Mixing old and new materials (e.g., copper with galvanized) can cause galvanic corrosion, so full replacement is often advised.

• Temporary Inconvenience: Homeowners may need to relocate or use portable facilities during the project.

Benefits of Repiping

• Improved Water Quality: Eliminates rust, lead, or sediment for safer, better-tasting water.

• Better Pressure and Flow: New pipes restore optimal water pressure and reduce clogs.

• Fewer Repairs: Reduces the need for frequent leak fixes, saving money long-term.

• Increased Home Value: Modern plumbing appeals to buyers and meets code standards.

• Energy Savings: Insulated PEX or copper reduces heat loss in hot water lines.